Mi swaco mogooes shale shaker screen api تصنيع

مجال التطبيق

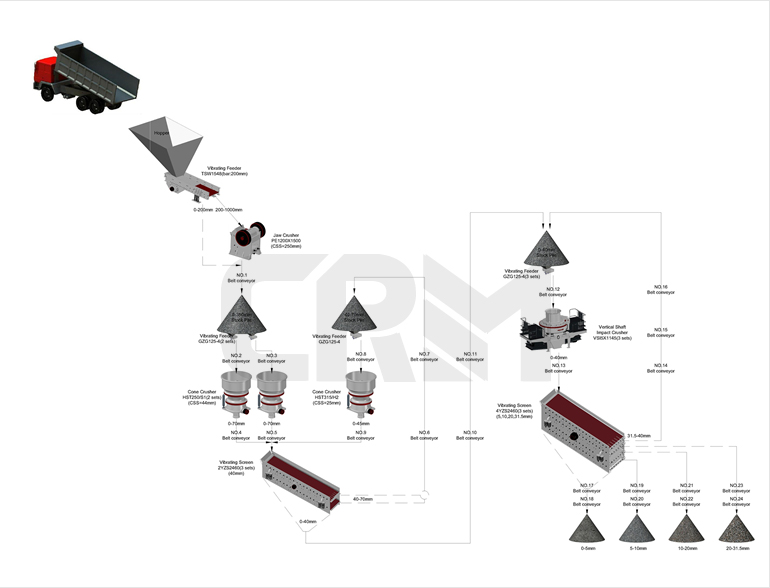

خط إنتاج معالجة البوكسيت 200TPH في غينيا

تم الإشادة بنظام التحكم الذكي Liming Heavy Industry. تمكننا من مراقبة خط الإنتاج المحلي في الوقت الفعلي ومعرفة معلومات الموقع في الوقت المناسب ، مما يوفر راحة كبيرة لإدارتنا.

المعدات: كسارة فكية PE750x1060 ، كسارة مخروطية هيدروليكية HPT300

المواد: البوكسيت

السعة: 200 طن / ساعة

حجم المدخلات: 600 مم

حجم الإخراج: 0-20mm.

التطبيق: إنتاج سبائك الألومنيوم ، التصنيع الحراري

M-I SWACO Shakers - SLB

Triple-deck shaker. Meet objectives for efficiency, flexibility, and rig space with an adaptable shaker in a compact package. View. View. M-I SWACO shakers deliver consistently high

MI-Swaco Mongoose Pro Shale Shaker

The MOnGOOse PRO shaker proved more than capable of handling the 12.25” section with an average ROP of 50 ft/hr and consistent flow rates at or near 660 gal/min, all while dressed with

MONGOOSE PRO - The OFMP

The MONGOOSE PRO Shale Shaker has a screen deck made of four pretensioned composite wire mesh screens. Each Shale Shaker screen is secured to the basket with two screen

DURAFLO Composite OEM Screens - Energy Dais

M-I SWACO high-capacity composite shaker screens are the most rugged, long-lasting and efficient screens available. Featuring a patented, composite frame design that holds up under

Swaco Shale Shaker Screen Replacement - Anping Shengjia

China manufacturer Shengjia provides replacement shale shaker screens as per API standards, which are compatible with Swaco Mongoose PRO, Meerkat PT, MD-2, MD-3, MAMUT and

API Mi-Swaco Mongoose Oil Shale Shaker Screen

API Oilfield Shale Shaker Screen. LFM shale shaker screens are available for the FLC Series. Brandt VSM, Cobra Series, Swaco Mongoose and KEM-TRON shale shakers, and we accept customized shale shaker screen, we has been the

MI Swaco Type – OilfieldScreens

API quality shaker screens, with dimension of 585 × 1165 mm, are manufactured for MONGOOSE MEERKAT shale shakers from M-I SWACO.

API RP 13c Mi-Swaco Mongoose Steel Frame Shale

SS wire mesh Mongoose Steel Frame Shaker Screens for remove drill cuttings. Constructed with two or three 304 or 316 stainless steel wire cloth layers with a steel backing plate and steel frame combined together. The bottom high

Replacement Shale Shaker Screen for MI Swaco - GN

GN provide replacement shaker screen for MI Swaco Shakers from API 10 to API 400. GN selected the best configuration of 3 layers of wire mesh for making the shaker screens. The accurate cut point of the shaker screen and high

Replacement Shale Shaker Screen for MI Swaco

OilFieldScreens provide a replacement shaker screen for MI Swaco Shakers from API 10 to API 400. OilFieldScreens selected the best configuration of 3 layers of wire mesh for making the shaker screens. The accurate cut point of the

M-I SWACO Shakers - SLB

Triple-deck shaker. Meet objectives for efficiency, flexibility, and rig space with an adaptable shaker in a compact package. View. View. M-I SWACO shakers deliver consistently high

M-I SWACO Shaker Screens - SLB

Enables remote and automatic control of MD-3 shakers to minimize personnel exposure to HSE risks. View. View. With more than 30 years experience in solids control and drilling waste

MI-Swaco Mongoose Pro Shale Shaker

The MOnGOOse PRO shaker proved more than capable of handling the 12.25” section with an average ROP of 50 ft/hr and consistent flow rates at or near 660 gal/min, all while dressed with

SWACO MONGOOSE/MEERKAT - Shaker Screen

Replacement screens for SWACO MONGOOSE PRO and MEERKAT PT shale shakers, the mesh type are XR, XL, HC, MG available and mesh range from API 8 to API 325. Keywords

MONGOOSE PRO - The OFMP

The MONGOOSE PRO Shale Shaker has a screen deck made of four pretensioned composite wire mesh screens. Each Shale Shaker screen is secured to the basket with two screen

Swaco Screen – Hebei Meihua Hardware Mesh Co., Ltd.

We can supply the replacement Mongoose’s steel frame and composite frame series shaker screens, our screen mesh is from API 20 to API 500. Product Specification. Product Display.

API 20 – API 400 - Shale Shaker Screen - MI-Swaco

Mongoose Shale Shaker Screen comes with either steel frame or composite material frame screen. H Screening produces both type of screens. We highly recommend the composite material frame screen which enjoys a longer

API Mi-Swaco Mongoose Oil Shale Shaker Screen

API Oilfield Shale Shaker Screen. LFM shale shaker screens are available for the FLC Series. Brandt VSM, Cobra Series, Swaco Mongoose and KEM-TRON shale shakers, and we accept customized shale shaker screen, we has been

DURAFLO Composite OEM Screens - Energy Dais

M-I SWACO high-capacity composite shaker screens are the most rugged, long-lasting and efficient screens available. Featuring a patented, composite frame design that holds up under

API RP 13c Mi-Swaco Mongoose Steel Frame Shale

SS wire mesh Mongoose Steel Frame Shaker Screens for remove drill cuttings. Constructed with two or three 304 or 316 stainless steel wire cloth layers with a steel backing plate and steel frame combined together. The bottom high

M-I SWACO – Original and Replacement Shaker Screen,

Shale shaker PARTS; SWACO BEM-600/650 Screen. ... Quick and easy to repair Less downtime Improved QHSE considerations M-I SWACO MONGOOSE, BEM-600/650, MEERKAT PT,SHAKER SCREENS. Details. SWACO ... Lower operating costs; Less down time M-I SWACO MONGOOSE shaker screen. Details. BLOG. The 2004 Solids Control API RP 13C – Part A;

API 20 – API 400 - Shale Shaker Screen - MI-Swaco

API 20 – API 400 - Mongoose Shaker Screen by H-Screening. Mongoose Shale Shaker Screen comes with either steel frame or composite material frame screen. H Screening produces both type of screens. We highly recommend

Mi Swaco MONGOOSE PRO Installation And

M‑I SWACO MONGOOSE PRO Shale Shaker 13.2 Operating Hazards Every action has been taken to ensure the Shale Shaker will function in a manner that is safe to the environment and the operator. However, there are certain

DERRICK® FLC™ 500, MI-SWACO® MONGOOSE™ BRANDT®

The EV DERRICK® FLC™ 500, MI-SWACO® MONGOOSE™ BRANDT® VENOM™ Replacement Screen provides the best quality Made in U.S.A Shaker Screen in the Industry. Our International and U.S.A. Patented Technology ensures you’ll receive the most durable, best performing replacement screen for your shaker unit.

Mi Swaco Shale Shaker API 70-XL (219 Microns) Mongoose Composite Oem Screen

Mi Swaco Shale Shaker API 70-XL (219 Microns) Mongoose Composite Oem Screen, Oem Number : API 70, Origin : ... Commented product: Mi Swaco Shale Shaker API 70-XL (219 Microns) Mongoose Composite Oem Screen Your review about the product?* 1 star(s) 2 star(s) 3 star(s) 4 star(s) 5 star(s) Quality: Price: Delivery: Your name * Comment Title * Your ...

Replace MI Swaco Screen

Replacement MI Swaco shale shaker screens for sale: BEM600, BEM650, ALS, ... APMG screen is replacement Mongoose series shaker screen from M-I SWACO. ... Screen layer: 2 or 3 layers: Mesh size: API 20—API 400: Wire mesh material: High quality S.S304L ~ S.S316L:

MI-Swaco Shaker Screen Replacement Shengjia

China manufacturer provides replacement shale shaker screens as per API standards., which are compatible with Swaco Mongoose PRO, Meerkat PT, MD-2, MD-3, MAMUT and ALS series shakers. Contact us now.

Replacement Shaker Screen for SWACO MONGOOSE/MEERKAT Shale Shaker

Screen Type: XL, XR, HC, MG. API RP 13C Designation: API 20 – API 325. Package: ... Both of them are ideally as the replacement screens of SWACO MONGOOSE PRO and MEERKAT PT shale shakers. ... SJ-M/M shaker screens are used as the substitute screen for: SWACO MONGOOSE PRO shaker. SWACO MEERKAT PT dual-motion shale shaker. Styles.

Setting the Bar in Solids Control - Aipu Shaker Screen

metal framed screens. Lower screen weight, in turn, enhances shaker G-force. Easy, Fast Screen Repair The patented SNAP-LOK † plug-repair system is available on DURAFLO composite screens for the M-I SWACO BEM-650† shale shaker and NOV Brandt VSM 300 shakers. The innovative SNAP-LOK plug-repair system reduces screen repair time to less

Shale Shaker Screen - Solids Control Shale Shaker

Shale shaker screens are becoming the most shaker parts as demands on the shale shaker have increased and developing. Aipu is focussed on resolving shaker screens’ three primary requirements: . High liquid and solids handling capacity . Acceptable life . Ability to be easily identified and compared Aipu screen instruction Aipu produces almost all shaker []

سابق: صخرة سحق المعدات PE150

التالي: مصانع تكسير الحجارة في اليمن

2-12-24SERVICE MECHANISM

Common choice of more than 170 countries

Email:[email protected]

المحادثة على الإنترنت

المحادثة على الإنترنت